Optimising pump systems to help water companies meet their 2030 net zero carbon target

- Client: Utilities

- United Kingdom

With water companies setting the bar for other infrastructure, utility and energy-intensive industries by aiming to achieve net zero carbon emissions by 2030, Andy O’Rourke, senior consultant at BGEN, explains the role control optimisation projects can have in helping the industry meet this ambitious target. He also gives examples of how Anglian Water has achieved significant carbon reduction savings in the field through optimising the control of pumping systems.

The race to 2030

In November 2020, UK water companies unveiled a ground-breaking plan to deliver a net carbon zero water supply for customers by 2030 in the world’s first sector-wide commitment of its kind1. Water UK has estimated this could save ten million tonnes of greenhouse gas by reaching net zero two decades ahead of the UK Government’s legally binding target of 2050.

The water industry is an energy intensive industry, with energy required to move and treat billions of litres of water per day, with each person in the UK consuming on average 142 litres1 per day. To meet the 2030 target, water companies are examining every facet of their operation to identify emission savings. This includes switching to low emission vehicles, realising water and energy savings, through to embracing renewable power and tackling process emissions.

Consequently, water companies are embracing new strategies to tackle leakage and examining their entire operation to identify energy saving opportunities. Pumps, an emitter of emissions, are one such area where water companies are looking for efficiencies and process improvements.

Pumps are fundamental in the water industry. They regulate the pressure in pumping mains to ensure water reaches its final destination, whether that be a storage reservoir or direct to customers. Pumps also remove and enable treatment of wastewater.

One of the key ways to improve the efficiency of pumping systems and reduce energy consumption is through effective control optimisation. An intelligent control system will pump only the required water when needed, and at the optimum pressure. This steady approach will also improve the treatment process and resilience through reduced leakage and bursts.

Realising control optimisation improvements at Anglian Water

Anglian Water, keen to look at how it could reduce its pump-related emissions across its operations, contacted BGEN to assist in meeting its 2030 target.

Anglian Water is the largest water and water recycling company in England and Wales by geographic area. The water company supplies water and water recycling services to almost seven million people in the East of England and Hartlepool. BGEN is a specialist, multi-discipline engineering solutions business. It has a dedicated team, providing engineering services across the utilities industry.

In delivering control improvements at Anglian Water, BGEN was responsible for a range of projects from conception to completion. Prior to each project taking place, BGEN gathered and analysed historical data from several sources to determine current and potential performance. A business case was then built to secure funding and upon approval the project was implemented in-house. Finally, the project was closed-out by verifying the delivered energy reduction against predicted savings.

The majority of the activity involved control modifications or re-designs, and offered leakage and process benefits alongside a reduction in CO2.

Three examples of optimising control systems are highlighted below:

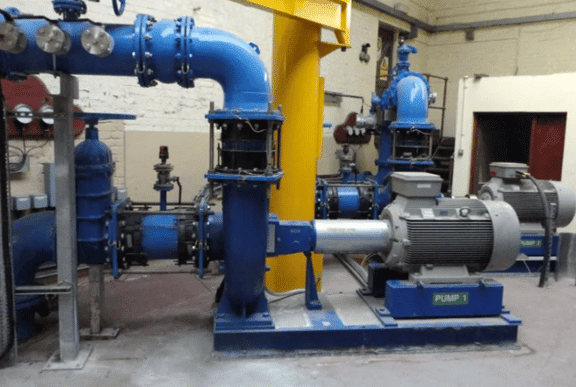

Intake raw water pumping station

A desktop study was undertaken to evaluate the efficiency and energy reduction opportunities at an intake raw water pumping station. It had been identified that a lack of automation was impacting on performance. The pumps were also split between low- and high-pressure units. The low-pressure units were inefficient at high pressures and vice versa.

To deliver the energy savings, a PLC was installed to provide automated control of the pumps, band-screens and valves to manage river and reservoir levels. This enabled calculation of the optimum target flowrate and the selection of the most efficient pump numbers and combinations (large or small).

Pressure optimisation

An intelligent control philosophy was designed by BGEN to smooth the demand on a major transfer pumping main. Modern variable speed drives were installed so that the pumps can reduce flow overnight (instead of completely stopping) to eliminate pressure surge and to better manage reservoir levels. This also reduced peak day flowrates and facilitated an optimised pressure/flow relationship, where the controlling pressure was calculated dynamically based on requirements.

Raw water pumping station

At another raw water pump station, it was identified that the existing control was inefficient and not making optimal use of the available assets. Due to the complexity of the system, a Front-End Engineering Design study was conducted to further analyse the system and verify potential savings.

To improve the efficiency of the station, BGEN used its Pump System Optimisation software which offers reduced energy consumption potential and storage volume management. As a result, the team optimised pump system flowrates, flow control and pump scheduling, which led to significant energy savings.

Making a difference

Through a number of control optimisation projects BGEN has achieved substantial carbon and cost savings for Anglian Water by reducing total emissions by 5,858 tonnes of embodied CO2 and total operating costs by £3 million. The projects were recognised at the Anglian Water Supplier Awards, where BGEN was awarded honours for Sustainability and Efficiency. Projects currently in delivery are set to realise further savings of 975 tonnes of embodied CO2, and circa £600,000 of savings per annum.

By water companies embracing the potential of optimising controls, they can make significant strides in their mission to achieve net zero emissions by 2030.