Vaporiser Replacement Project

Client Requirement

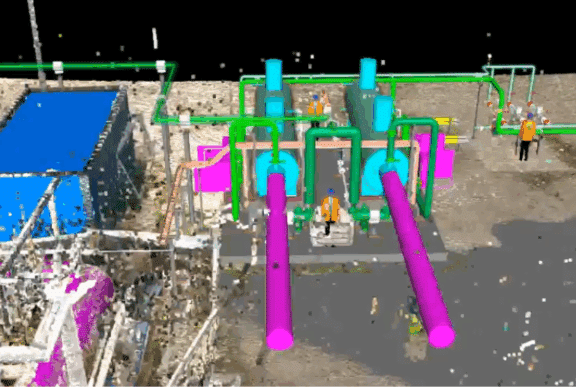

Our client an industrial gas supplier, required the replacement of two ageing steam backup vaporisers at their Stanlow facility following a failure in one of the original 1978 units. The new installation needed to increase capacity by introducing 2 x 100% design flow steam vaporisers (replacing the previous 60% units) and integrate seamlessly into the existing infrastructure. The project also required tie-ins to existing steam, liquid nitrogen, and gaseous nitrogen pipework, while maintaining compliance with current industry standards.

Our Solution

BGEN carried out front-end design and engineering development to support the client in assessing options for installing the new vaporisers. We provided costed proposals for two approaches:

- Skid-mounted units, fabricated and preassembled off-site.

- Concrete plinth-mounted units, stick-built on-site.

The client opted for installation on concrete plinths, which provided a robust and cost-effective long-term solution. Our team delivered the replacement works with a focus on improving equipment layout, ensuring tidier routing, and prioritising ease of maintenance compared to the legacy installation.

Challenges Faced

- Integration into an existing facility: All works had to tie into the live plant’s existing systems with minimal disruption to ongoing operations.

- Space and layout constraints: The project involved working within the footprint of the established plant, requiring precise planning and sequencing.

- Programme management: Balancing the client’s need for efficiency with the realities of civil and mechanical works on an operational site.

Client Benefits

- Future-proofed equipment: The new vaporisers are compliant with modern safety and engineering standards.

- Improved maintenance access: The redesigned layout ensures easier upkeep and reduced downtime risk.

- Cost and efficiency balance: By selecting concrete plinth-mounted units, the client achieved significant cost savings compared to skid-mounted fabrication, while still benefiting from a well-structured installation.

- Enhanced reliability: The new installation ensures the facility can continue to act as a dependable backup to the main production site, reducing operational risks.