Global Glass Producers

Client requirements

A leading global glass producer, required a robust and customised Motor Control Centre (MCC) for their coater facility.

BGEN was appointed to deliver the project from their manufacturing facility in the heart of Warrington; and appointed to manufacture, Test and prepare the unit for delivery.

Our solution

With the client’s design specification, BGEN was responsible for the manufacturing, Testing and delivery; following the ‘Free Issue’ design schematic, ensuring adherence to their design and build requirements.

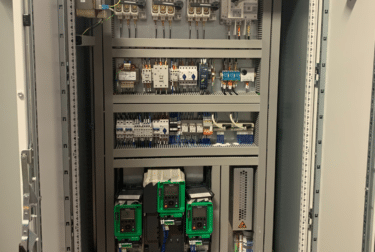

We constructed the MCC using Form Two, Rittal Cabinet Wardrobe Style, known for its durability and flexibility in industrial environments; complimented by electrical integration, incorporating a 250A Incomer and a control 24V supply section, ensuring robust power management and control within the MCC.

Complimented by Free Issue PLC Hardware and Software, ensuring seamless integration with the client’s existing systems. Each of the five starter wardrobe sections was equipped with a common isolator switch for safety and operational control, three variable speed drives protected by individual fuse switches and contactors for reliable operation, hardwired I/O modules for efficient communication with the PLC section, fans and filters to manage cooling requirements, and field motor terminals for easy connection and maintenance.

A Client Factory Acceptance Testing (CFAT) was carried out to ensure all components and systems functioned correctly and met the client’s stringent quality standards. Post-testing, the MCC was prepared for delivery to the UK packers, with all necessary documentation and handling instructions. We coordinated closely with logistics partners to ensure timely shipment aligning with the projects timelines.

Client Benefits

The client benefited significantly from our manufacturing as the MCC was built precisely to their specifications, ensuring compliance with their design and operational requirements.

High-quality components and rigorous testing ensured the reliability and longevity of the MCC.

The use of Free Issue PLC Hardware and Software facilitated seamless integration with existing systems, minimising disruption and additional configuration efforts.