The ‘nuts and bolts’ of a mechanical audit, as told by quality control.

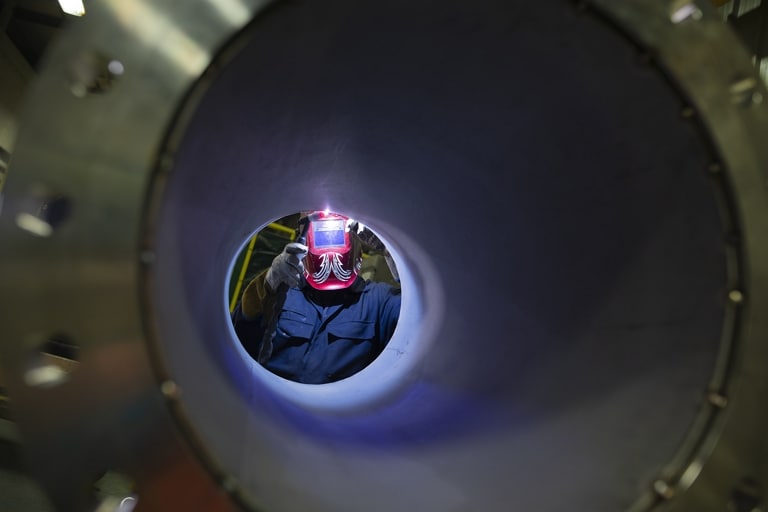

Earlier this year, our mechanical fabricators, based in St Helens, undertook our annual audit for TWI (The Welding Institute) BS EN ISO 3834-1:2021 Welding Quality and BS EN 1090 Structural Steel and Aluminium.

We wanted to share an insight about what this involves, so Quality Control Manager, Michael Johnson, talked us through what the auditing process entails and what our quality assurance capabilities are in this area.

Can you explain a little bit about your role?

I have been a Quality Control/Quality Assurance Manager for many years gathering invaluable experience throughout many major projects

I wear many hats here, one of which is overseeing our QMS (Quality Management System), which ensures that we have a good and functional quality management system in place. This increases efficiency, better employee morale and credence in the international business arena. You can learn what improvements are needed by fact finding within a system of documentation and analysis, which in turn inspires confidence from our clients and customers. It is also obviously very helpful to have a robust QMS for auditing purposes, which in turn is proof to our clients that we are trustworthy, responsible, and knowledgeable.

I am also a Responsible Welding Coordinator according to ISO 14731, which is someone who can competently apply good practice in all welding activities. This is an important requirement and is included to ensure the manufacturer understands the problems which can arise and how they can be avoided. RWC has a responsibility for all welding activities, so the knowledge and competency of the Responsible Welding Coordinator is of paramount importance.

Tasks and responsibilities include welding engineering, welding supervision, material selection, NDE control and management, quality control management, and review and analysis of contract requirements.

Who is the notified body that carries out this audit?

At this facility, everything is audited by The Welding Institute. There are a few different notified bodies and there are many that we work with in other areas for Health and Safety or Quality auditing. However, in the world of welding, we find that TWI accreditation holds a lot of sway with many of our clients, who are very specifically focused on this one aspect of a project and have been involved with welding their whole lives. Whilst TWI could be perceived as being more stringent or intensive, we see this as a good thing: the bar must be very high, and this helps us when conveying our capabilities.

What is checked during this audit?

In the annual audit, the auditors are with us for two days (in the five-year audit, this goes up to one week). The auditors make sure that we are compliant with the latest standards. There are both British Standards BSEN and American standards ASME which we are audited for regarding all elements: welding, quality, design, NDT, production/ fabrication etc. on all projects we are currently working on, as well as completed historic projects. We show technical reviews to prove we have done all due diligence on each project we have been working on.

The auditors also check on how and where all testing takes place (much of which is done in-house). All testing operators must go through a PCN certification to prove that they operate to code: Minimum PCN Level 2 certification is required.

As well as the mechanical facility itself, the auditor was impressed by how our electronic QMS (Quality Management System) is organised in terms of where qualifications are stored and managed, and the knowledge that we have within our team.

What are some of BGEN’s quality and conformity features pertaining to fabrication?

UCKA and European marking.

B-Gen currently has UK Conformity Assessed (UKCA) marking, which indicates conformity with the applicable requirements for products sold within Great Britain. After this audit we intend to also hold EU CA Conformity Assessed marking applicable requirements for products sold within EU.

All our items have UKCA marking (if you don’t know about this subject you can read our article). Whilst we are fabricating under UKCA, we can develop parts for UK and Africa, and the recent TWI audit has also put us in line for the European CE next year, which readies us for some of our upcoming projects

Welding Inspectors and RWC’s.

All BGEN Welding Inspectors are qualified as CSWIP* 3.1 level minimum, with extensive, experience, resulting in a very high level of quality products being manufactured by B-Gen. As a responsible company we recognise that we should increase the level of knowledge internally, so I have been actively upskilling an individual within our existing team to become a CSWIP 3.2 senior welding inspector and RWC (Responsible Welding Coordinator). This person has been part of the team for a long time, so it’s great to be able to offer this kind of progression to those who understand the day to day running of the challenges of complex projects.

Specialist testing capabilities

Visual Testing (VT): Visual Non-Destructive Testing is the act of collecting visual data on the status of a material. Visual testing is the most basic way to examine a material or object without altering it in any way.

Visual Testing can also be done with an RVI (Remote Visual Inspection) tool, like an inspection camera such as a borescope. The benefits of borescope rather than a standard ‘pipe inspection camera’ is the ability to enter smaller pipe. Flexible borescopes are useful when examining complicated geometry pipe work or machinery.

Olympus Industrial Videoscopes streamlines all aspects of on-site inspections. It greatly improves our work efficiency by organising stored images and detailed inspection reports. Magnetic Particle Inspection (MPI) and Dye Penetrant Inspection (DPI) – both methods of surface testing – are also performed in-house, as our operators are qualified to Level 2, which is a minimum requirement for this type of testing.

We have very professional subcontractors who can carry out any kind of special method required for major projects. The subcontractors we partner with are skilled to test under all the latest technologies of NDT (Non-destructive testing) including: Ultrasonic Testing (UT), Radiography Testing (RT) and Manual Phased Array (MPA).

QMS

We ensure that anything that is related to any of the standards that we work to is adhered to and traceable within our QMS. This also involves being alert to any changes or updates, keeping completely current and accurate records and storing all relevant documentation correctly.

Anything else we might want to know?

It is key to point out that quality is attained as a whole team and built in to our culture every day. It would be hopeless for me to just try to run the quality department if I didn’t have open communication and collaboration across the board with everyone here at the facility, and all of our partners. The importance of teamwork cannot be stressed enough! A leader who can’t work with a team, is a failure.

*CSWIP is a level also achieved through the TWI CSWIP certification schemes are UKAS-accredited to ISO/IEC 17024, the international standard for personnel certification. The CSWIP certificates support compliance with customer requirements, standards and regulations, and provide assurance to employers that personnel are competent and can deliver the job role.