Process treatment plant

Services provided

Client Requirement

Our client required a sustainable and reliable solution for one of its key water treatment facilities.

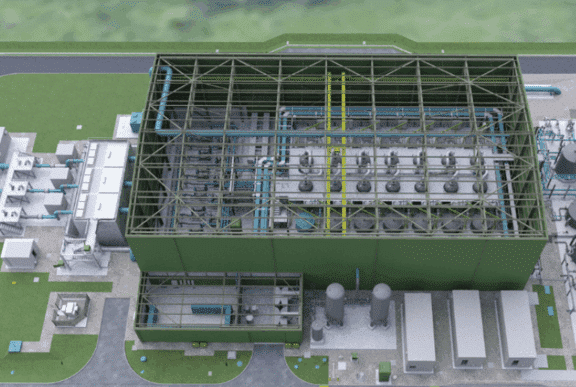

The objective was to strengthen water supply resilience, enhance operational efficiency, and meet stringent water quality standards. A central element of the project was the Ceremac membrane building, a critical component of the treatment process.

BGEN was engaged to deliver essential installations and components that would ensure the facility’s successful operation.

Our Solution

BGEN supported the project by delivering and installing critical systems within the Ceremac membrane building, the first stage of the treatment process.

We supplied and installed advanced electrical control panels to provide precise monitoring and control of treatment operations. Each panel was factory-tested before installation, ensuring seamless integration with the site’s existing infrastructure and delivering improved reliability and performance.

In parallel, BGEN delivered high-quality water quality instrumentation boards to provide operators with accurate, real-time data. These systems are essential for ensuring compliance with regulatory standards and allow proactive adjustments to be made throughout the treatment process.

To further enhance operational resilience, we installed fast-acting pneumatically actuated butterfly valves, supplied by AVK UK Ltd. These valves enable rapid responses during both operational processes and backwash cycles, ensuring the plant can operate efficiently and recover quickly from any disruptions.

Client Benefits

- Capacity to process and deliver 65 million litres of high-quality water daily, securing supply for 224,000 households.

- Exceptional microfiltration and fouling resistance from the ceramic membrane system, reducing downtime and maintenance needs.

- 25-year design life of the membranes, significantly lowering long-term operational costs.

- Value engineering that freed up funding for reinvestment in process resilience and risk mitigation.

- Factory-tested and pre-assembled components, ensuring a streamlined installation and on-time delivery for commissioning in May 2025.

- Full compliance with Drinking Water Inspectorate standards, guaranteeing safe and high-quality water for the community.