FMCG Project Delivered By BGEN

Client Requirement:

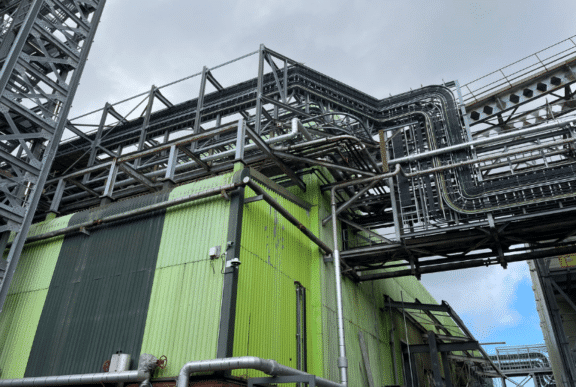

One of our FMCG clients required a comprehensive overhaul of their facility, which was built in the early 1980s and had become outdated and inefficient. The site, processing rape seed into products for various markets, needed to replace six obsolete Vertical Flake Cookers that were costly to maintain and unlikely to pass legislative testing.

With a long-standing partnership, BGEN was appointed to remove the cookers, redundant equipment, services, and support steelwork, and install new equipment and conveying routes, including electrical services and rewiring of the process equipment.

Our Solution:

We aligned our project team with the client’s objective and provided a comprehensive M&E solution adopting a phased approach to optimise workflow and resource allocation. Preparatory work, including site assessments, work sequencing and mechanical and electrical equipment installations followed by a planned four-week 24/7 shutdown.

The relocation of redundant platforms and conveyors was executed with precision, minimising disruption to ongoing plant operations and allowing the team to carry out critical work, including removal of the cookers and redundant systems, installing new equipment: ChainConveyors, Agitated Vessel and Rotary Magnet, and rewiring necessary process equipment whilst working to a tight schedule in a challenging environment. To complement the new equipment, modifications were carried out to the MCC building to optimise performance and improve the process.

We remained on the live operational site going through snagging with rigorous safety protocols finalising installations, conducting tests, and ensuring seamless integration with existing plant infrastructure. Throughout the project, we maintained open communication channels with the clients team, facilitating real-time collaboration and issue resolution.

Detailed documentation and quality assurance processes were implemented to track progress and ensure compliance with project specifications. The project was delivered on time and within budget, ultimately delivering a solution that the clients requirements for efficiency, safety, and reliability.

Client Benefits:

The client significantly reduced maintenance costs and improved operational efficiency by removing outdated cookers and ensuring compliance with legislative standards.

Future Scalability: The phased approach minimised plant downtime, ensuring operational continuity. The reserved space for future equipment provides flexibility for process improvements.

Cost-Effective: BGEN’s comprehensive solution reduced the need for multiple contractors, resulting in cost savings and a more efficient project delivery timeline.

Safety and Compliance: The project adhered to rigorous safety and compliance standards, ensuring the safety of both the facility and its personnel.