Diageo Brewery Development in Ethiopia

Services provided

Client Requirement

Diageo sought a turnkey solution to build a state-of-the-art brewery in Ethiopia, meeting high international standards for efficiency and sustainability. The project required the installation of a 3000kVA generator and a 15kV high voltage switchboard for reliable power supply, as well as an advanced automated control system for operational efficiency. Along with mechanical systems to improve their operations.

Our Solution

We implemented a complete turnkey solution, drawing on our extensive expertise in mechanical, electrical, and instrumentation (M, E & I) systems. Our approach involved installing a 3000kVA generator and a 15kV high voltage switchboard to ensure an uninterrupted power supply and an automated control system to optimise brewery operations.

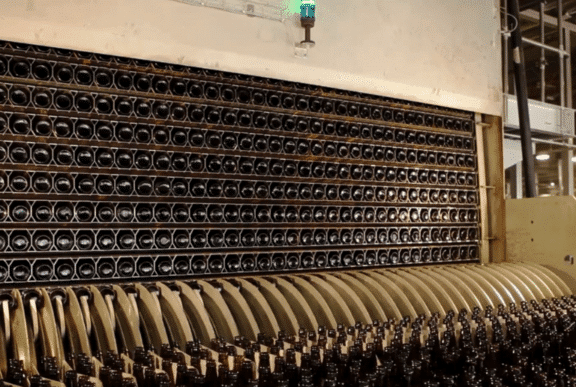

The mechanical systems we implemented included a 36-tonne steam boiler and stainless steel hot well for efficient steam generation and storage. Pipe bridges and walkways were constructed to facilitate safe movement and maintenance of infrastructure, and comprehensive bottling line services with specialised pipework were provided.

We managed the procurement and shipment of equipment from multiple international suppliers, coordinating the delivery of sea and air freight shipments. We navigated shipping challenges with our international project experience, ensuring timely delivery of essential equipment to the Ethiopian site.

Our UK-led management team, comprised of skilled professionals, ensured that high UK and EU standards were maintained throughout the project. Additionally, we focused on sustainability by reducing the carbon footprint and achieving cost savings through efficient design and implementation, while facilitating a knowledge transfer to the local workforce.

Client Benefits

The turnkey solution delivered several benefits to Diageo, including enhanced operational efficiency due to the automated control system and optimised power supply, reducing downtime and operational costs.

The implementation of LED lighting and efficient systems led to a reduced carbon footprint and significant cost savings over the project’s lifespan.

Adherence to high UK and EU standards ensured quality and reliability in all aspects of the brewery’s development, and the knowledge transfer to the local workforce boosted local skills and supported economic growth.

Despite the logistical challenges of transporting equipment to a remote location, the project was completed within budget and on schedule, ensuring a timely start to brewery operations.