The Advantages of Offsite Construction in Critical Controlled Environments

Precision, compliance, sustainability, and operational efficiency are paramount in a critical controlled environment and, the choice of construction methods can profoundly influence the success of critical controlled environments. Modular or offsite construction, with its innovative approach and adaptable nature, is swiftly emerging as the cornerstone of transformative solutions across various sectors. With, many suppliers now providing sustainable solutions that can help future scalability, profitability and minimise your carbon footprint.

Driving Efficiency Through Innovation

According to a report by McKinsey & Company “Modular Construction: From Projects to Products”, modular construction can reduce project schedules by up to 50% compared to traditional methods, resulting in significant time and cost savings. This streamlined approach benefits the installation of complex mechanical and electrical systems required in pharmaceutical manufacturing facilities, energy infrastructure projects, water treatment plants, FMCG production facilities and data center’s.

By fabricating pre-made modules off-site concurrently with on-site preparations, modular construction minimises operational downtime and ensures timely project delivery, thereby enhancing overall project ROI.

Furthermore, Research by the National Institute for Occupational Safety and Health (NIOSH) indicates it reduces on-site accidents and injuries by up to 35% compared to traditional construction methods. As a result, minimum downtime.

Embracing Sustainability and a Low Carbon Future

Modular construction stands as a beacon of eco-consciousness in the construction industry. According to research by the Modular Building Institute “Modular Building Institute’s Modular Construction Research”, modular construction can reduce construction waste by up to 90% and lower energy consumption during the construction phase by up to 67%. This sustainable alternative optimises material usage and minimises waste through precision manufacturing in controlled factory settings.

Furthermore, the modular assembly process generates fewer on-site emissions and disturbances, providing a more sustainable and low carbon construction approach. By reducing transportation requirements and harnessing sustainable materials, modular construction not only minimises carbon emissions but also aligns with wider sustainability goals, fostering a more sustainable future for critical controlled

environments. Benefiting industries that require stringent environmental standards, such as pharmaceuticals and water treatment.

“Offsite and modular construction methods have many environmental benefits, from reducing waste and carbon emissions, to creating sustainable supply chains. By harnessing these benefits, we are reducing the impact of our operations and playing a real part in the journey to Net Zero.”

Amy Twist, Head of Sustainability at BGEN

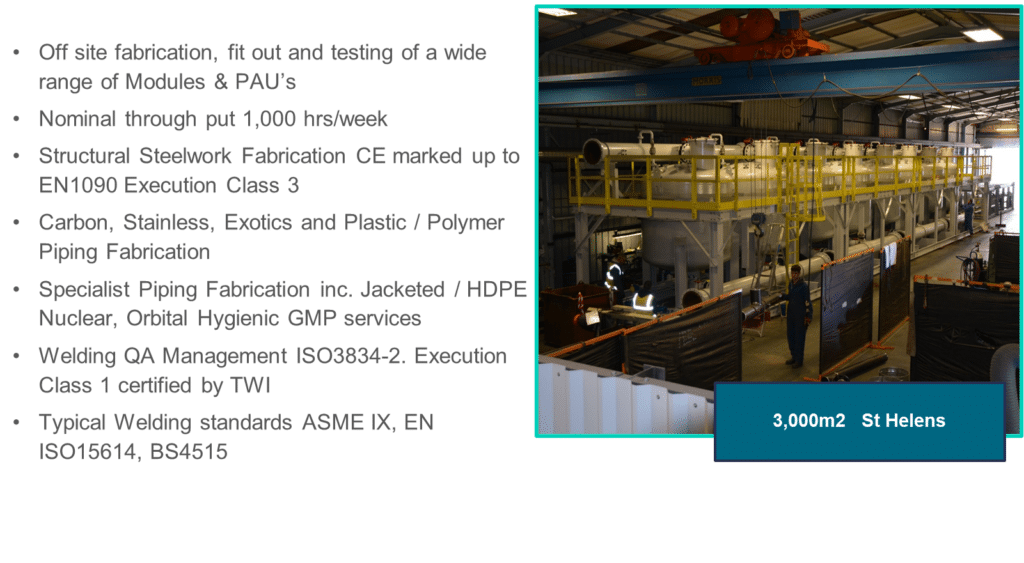

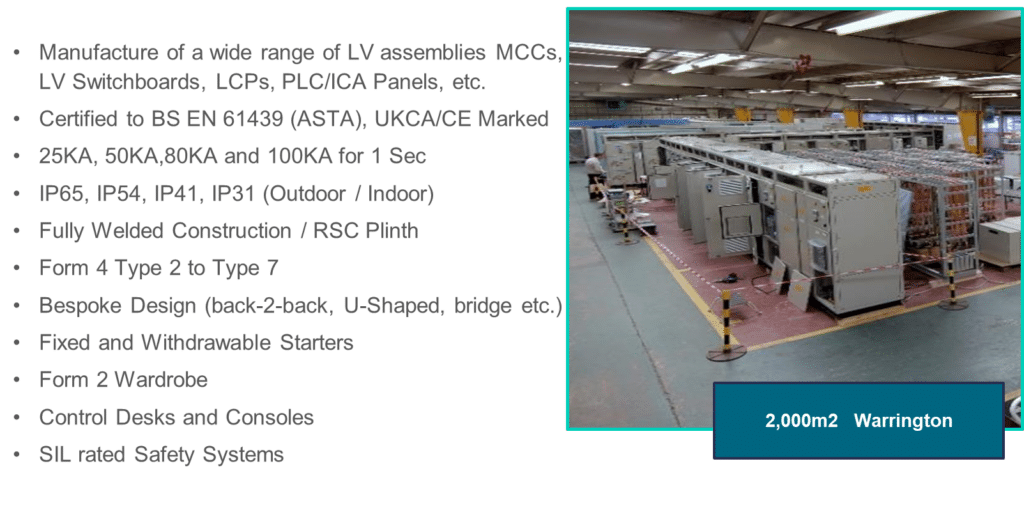

BGEN have offsite fabrication facilities designed to support the requirements of the water, pharmaceutical, industrial, energy and FMCG market. Allowing them to offer a full turnkey solution and as a result they’re able to ensure speed to market, quality and scalability completed to regulatory standard.

Empowering Adaptability for Future-Proof Solutions

In an increasingly dynamic business landscape, characterised by rapid technological advancements and shifting market demands, adaptability is key to sustained success. According to a study by Dodge Data & Analytics “The Drive Toward Healthier Buildings 2016: Tactical Intelligence to Transform Building Design and Construction SmartMarket Report”, 62% of respondents in the construction industry believe that modular construction improves project schedule performance, while 53% agree that it enhances productivity.

Modular construction empowers clients with unparalleled adaptability, enabling swift responses to evolving needs and market conditions. Whether it’s scaling up pharmaceutical production capacities, expanding energy infrastructure, upgrading water treatment facilities, or optimising production lines in FMCG facilities. The inherent flexibility of modular design allows for easy reconfiguration and expansion, ensuring that critical controlled environments can seamlessly accommodate changing operational requirements. Modular facilities offer a future-proof solution that aligns with the ever-changing needs of modern industries.

Unlocking Value Across Industries

From pharmaceuticals to energy, and beyond, the advantages of modular construction reverberate across diverse industries. By maximising efficiency, embracing sustainability, and empowering adaptability, modular construction transcends mere construction methodology—it becomes a catalyst for transformative change. As clients continue to embrace modular construction in critical controlled environments, the ripple effects of its benefits will be felt across sectors, driving increased efficiency, sustainability, and competitiveness in the global market.

Modular construction represents not just a trend but a fundamental shift in how critical controlled environments are conceived, constructed, and utilised. By harnessing the power of innovation, sustainability, and adaptability, modular construction offers clients unparalleled advantages in navigating the complexities of today’s industrial landscape. As we look towards the future, the potential of modular construction to revolutionise critical controlled environments remains limitless, paving the way for a more efficient, sustainable, and resilient future across industries.

BGEN have the capabilities inhouse to deliver a full turnkey solution from concept to commissioning and validation meeting all compliance and regulatory requirements. With their in-house offsite fabrication facilities, you have the guarantee of project delivery of the highest standard that offers scalability and future proof of your operations.

To find out more about BGEN’s expertise visit: https://b-gen.co.uk/expertise/